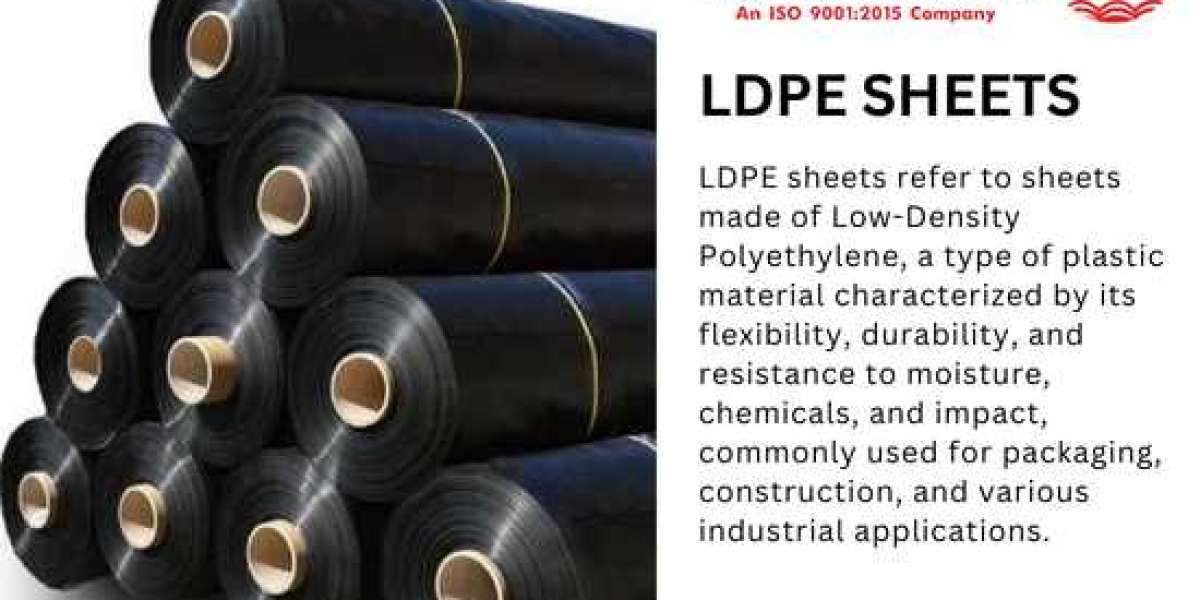

LDPE Sheet Manufacturer in India, short for Low-Density Polyethylene sheets, are versatile materials with a wide range of applications across various industries. From packaging to construction, LDPE sheets offer durability, flexibility, and cost-effectiveness. In this comprehensive guide, we'll delve into the uses, advantages, and frequently asked questions about LDPE sheets.

Uses of LDPE Sheets:

Packaging: LDPE Sheet Manufacturers in Ahmedabad are commonly used for packaging due to their flexibility and ability to withstand varying temperatures. They are ideal for wrapping products, protecting them from moisture, dust, and other contaminants.

Construction: LDPE sheets serve as protective barriers in construction projects. They can be used as damp proof membranes, vapor barriers, and insulation materials.

Agriculture: In agriculture, LDPE sheets are used for greenhouse covering, mulching, and protecting crops from pests and harsh weather conditions.

Medical Industry: LDPE sheets are used in medical applications such as disposable gloves, aprons, and medical packaging due to their non-toxic nature and flexibility.

Manufacturing: They are utilized in manufacturing processes for creating molds, gaskets, and protective covers due to their moldability and chemical resistance.

Advantages of LDPE Sheets:

Flexibility: LDPE Sheets Exporters in Ahmedabad are highly flexible, making them easy to mold and shape according to specific requirements.

Chemical Resistance: They exhibit excellent resistance to a wide range of chemicals, making them suitable for various industrial applications where chemical exposure is a concern.

Waterproof: LDPE sheets are waterproof, making them ideal for outdoor applications and situations where moisture resistance is crucial.

Cost-Effective: Compared to other materials, LDPE sheets are cost-effective, offering a balance between performance and affordability.

Recyclable: LDPE is recyclable, contributing to sustainability efforts by reducing environmental impact and promoting circular economy practices.

Conclusion:

LDPE sheets are indispensable materials with diverse applications across industries. Their versatility, durability, and cost-effectiveness make them a preferred choice for packaging, construction, agriculture, and more. By understanding their uses, advantages, and addressing common questions, businesses and consumers can harness the full potential of LDPE sheets while minimizing environmental impact through responsible usage and disposal practices.

FAQs About LDPE Sheets:

What is LDPE?

LDPE stands for Low-Density Polyethylene. It is a thermoplastic polymer characterized by its low density, flexibility, and chemical resistance.

Are LDPE sheets suitable for outdoor use?

Yes, LDPE sheets are suitable for outdoor use due to their waterproof nature and ability to withstand varying weather conditions.

Can LDPE sheets be recycled?

Yes, LDPE sheets are recyclable. They can be collected, processed, and reused to manufacture new products, contributing to sustainability efforts.

Are LDPE sheets food safe?

LDPE sheets are generally considered food safe. However, it's essential to ensure that they comply with relevant regulations and standards for specific food packaging applications.

What thicknesses are LDPE sheets available in?

LDPE sheets are available in a wide range of thicknesses, typically ranging from 0.5 mil to 40 mil, catering to various application requirements.

Can LDPE sheets be welded or sealed?

Yes, LDPE sheets can be welded or sealed using techniques such as heat sealing, ultrasonic welding, or adhesive bonding, depending on the specific requirements of the application.

Are LDPE sheets UV resistant?

While LDPE sheets offer some degree of UV resistance, prolonged exposure to sunlight may cause degradation over time. Additives can be incorporated into LDPE formulations to enhance UV resistance for outdoor applications.

What are the environmental implications of LDPE?

LDPE, like other plastics, can have environmental implications if not properly managed. However, efforts such as recycling, proper disposal, and exploring alternative materials help mitigate its environmental impact.